X - 43 Ramjet

X-43 Hyper-X Program

NASA established a multi-year experimental hypersonic ground and flight test program called Hyper-X. The program sought to demonstrate "air-breathing" engine technologies that promise to increase payload capacity or reduce vehicle size for the same payload for future hypersonic aircraft and/or reusable space launch vehicles. Hydrogen will fuel the program's research vehicles, but it requires oxygen from the atmosphere to burn.  Planned X-43B flights were to occur sometime in 2009 after the completion of another Hyper-X test vehicle, the X-43C. The NASA/industry Hyper-X program sought to demonstrate airframe-integrated, "air-breathing" engine technologies that promise to increase payload capacity for future vehicles, including hypersonic aircraft (faster than Mach 5) and reusable space launchers. Prior flight experiments conducted by the Russians using a rocket booster have demonstrated air-breathing engine operation at Mach 5 to 6 conditions. Extending air-breathing technologies to much greater speeds requires the development of scramjet engines

Planned X-43B flights were to occur sometime in 2009 after the completion of another Hyper-X test vehicle, the X-43C. The NASA/industry Hyper-X program sought to demonstrate airframe-integrated, "air-breathing" engine technologies that promise to increase payload capacity for future vehicles, including hypersonic aircraft (faster than Mach 5) and reusable space launchers. Prior flight experiments conducted by the Russians using a rocket booster have demonstrated air-breathing engine operation at Mach 5 to 6 conditions. Extending air-breathing technologies to much greater speeds requires the development of scramjet engines

Conventional rocket engines are powered by mixing fuel with oxygen, both of which are traditionally carried onboard the aircraft. By eliminating the need to carry oxygen aboard the aircraft, future hypersonic vehicles will have room to carry more payload. NASA Dryden had several major roles in Phase I of the Hyper-X program, which was a joint Dryden/NASA Langley Research Center program conducted under NASA's Aeronautics and Space Transportation Technology Enterprise. Dryden's primary responsibility was to fly three unpiloted X-43A research vehicles to help prove both the engine technologies, the hypersonic design tools and the hypersonic test facilities developed at Langley.

Fly three unpiloted X-43A vehicles between January 2000 and September 2001.

Evaluate the performance of the X-43A research vehicles at Mach 7 and 10.

Demonstrate the use of air-breathing engines during flights of the X-43A vehicles.

Provide flight research data to validate results of wind tunnel tests, analysis and other aeronautical research tools used to design and gather information about the vehicles.

As the lead Center for the flight-research effort, Dryden engineers worked closely with their colleagues from Langley and industry to refine the design of the X-43A vehicles. Dryden also managed the fabrication of both the X-43A vehicles and the expendable booster rockets to serve as launch vehicles. Dryden also performed flight-research planning as well as some vehicle instrumentation and provided control of the tests.

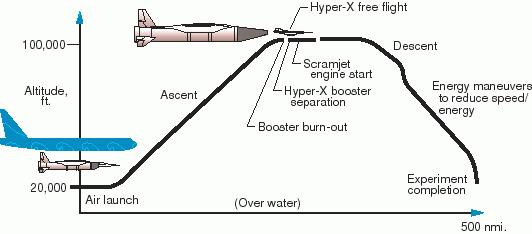

For each flight the booster will accelerate the X-43A research vehicle to the test conditions (Mach 7 or 10) at approximately 100,000 feet, where it separates from the booster and fly under its own power and preprogrammed control. The flight profile calls for launching the X-43A vehicles heading west. The flight path for the vehicles varies in length and is completely over water.

The B-52 Dryden used to carry the X-43A and launch vehicle to test altitude is the oldest B-52 on flying status. It is one of two B-52s used to air launch the three X-15 hypersonic aircraft for research flights.

Modified Pegasus® boosters will serve as the launch vehicles.

On 11 August 1998, the first piece of hardware was delivered to NASA - a scramjet engine that was used for a series of ground tests in NASA Langley's 8 Foot High Temperature Tunnel. This engine could later be used for flight if necessary.

The first flight engine was to be mated to the X-43 flight vehicle in February 1999 and delivered to NASA Dryden leading to the first flight of the program in early 2000. NASA selected MicroCraft Inc., Tullahoma, Tenn., in March 1997 to fabricate the unpiloted research aircraft for the flight research missions, two flights at Mach 7 and one at Mach 10 beginning in 2000. Micro-Craft is aided by Boeing, which is responsible for designing the research vehicle, developing flight control laws and providing the thermal protection system; GASL Inc., which is building the scramjet engines and their fuel systems and providing instrumentation for the vehicles; and Accurate Automation, Chatanooga, Tenn.

The first X-43A Hyper-X program research vehicle was launched on 02 June 2001. The flight failed because the vehicle's control system design was deficient in several analytical modeling areas, which overestimated the system's margins. The final flight of NASA's X-43A hypersonic research aircraft took place 16 November 2004. The mission flight-validated the operation of the X-43A's supersonic-combustion ramjet - or scramjet - engine at a record airspeed of almost Mach 10, or 10 times the speed of sound. NASA's X-43A scramjet-powered research vehicle broke the air speed record November 16 and showed that an "air-breathing" engine can fly at nearly 10 times the speed of sound. It was the fastest of three unpiloted tests in NASA's Hyper-X Program to explore an alternative to rocket power for space-access vehicles.

Air-Breathing Scramjet Engine Technologies

This challenging ground and flight-research program will expand significantly the boundaries of air-breathing flight by being the first to fly a "scramjet" powered aircraft at hypersonic speeds. Demonstrating the airframe-integrated ramjet/scramjet engine tops the list of program technology goals, followed by development of hypersonic aerodynamics and validation of design tools and test facilities for air-breathing hypersonic vehicles. The scramjet engine is the key enabling technology for this program. Without it, sustained hypersonic flight could prove impossible.

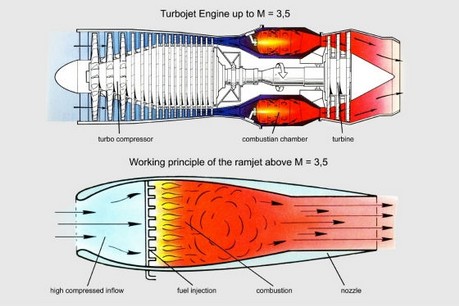

Unlike jet engines, ramjets have no rotating parts. Ramjets operate from about Mach 2 to Mach 5.

Scramjets (supersonic-combustion ramjets) are ramjet engines in which the airflow through the whole engine remains supersonic. Long duration, full-scale testing requires flight research. Hyper-X will help build knowledge, confidence and a technology bridge to very high Mach number flight.

The highest speed attained by NASA's rocket-powered X-15 was Mach 6.7. The X-43A aircraft is designed to fly faster than any previous air-breathing aircraft.

X-43B Revolutionary Turbine Accelerator (RTA)

NASA will develop, test and fly the Hyper-X series over the next two decades to support development of future-generation reusable launch vehicles and improved access to space.

The Turbine-Based Combined Cycle (TBCC) engine project seeks to deliver a Mach 4+ hypersonic propulsion system in this decade. Prime among its enabling technologies: the Revolutionary Turbine Accelerator (RTA), intended to demonstrate high mach turbine performance and durability for space access.

The Next Generation Launch Technology program tasked NASA's Glenn Research Center to lead high-Mach turbine propulsion development projects, including the TBCC/RTA effort. The state-of-the-art in high Mach turbine engine technology is the J-58. By 2015 the RTA project seeks to advance high Mach turbines to 35% increase in Mach number, 375% higher T/W, and 4 times improved critical component life. The RTA project consists of the development and test of a mid-scale ground-based turbine accelerator demonstrator and a possible sub-scale turbine accelerator flight demonstrator with Dual Mode Scram Jet (DMSJ) for an X43-B test flight vehicle.

The mid-scale RTA Ground Test Engine (GTE) would evaluate & demonstrate Mach 4+ turbo machinery and the advanced technologies required to reach Mach 4.

Engine cycle performance and operability;

Reliability & Durability of High Mach turbine components;

Inlet and nozzle integration with engine;

Geae is wokring with NASA GRC to develop the RTA for a new Mach 4+ engine.

The augmentor will transition to a ramburner between Mach 2 and 3 which will then accelerate the vehicle to speeds above Mach 4.

The air-breathing, hypersonic X-43C, is part of NASA's Hyper-X series of flight demonstrators. NASA will develop, test and fly the Hyper-X series over the next two decades to support development of future-generation reusable launch vehicles and improved access to space.

On 08 October 2003 NASA selected Allied Aerospace Industries of Tullahoma, Tenn., to provide three flight-ready demonstrator vehicles that will fly approximately 5,000 miles per hour or seven times the speed of sound. The multi-year project, called X-43C, will expand the hypersonic flight envelope for air-breathing engines.

The X-43C is the next logical step, following the current Hyper-X (X-43A) vehicle that aims at demonstrating short duration scramjet powered flight at Mach 7 and Mach 10. The X-43C will demonstrate free flight of a scramjet-powered vehicle with acceleration capability from Mach 5 to Mach 7, as well as operation of a hydrocarbon fuel-cooled scramjet.

NASA's Langley Research Center, Hampton, Va., is leading a combined U.S. Air Force/industry team in the design and development of the X-43C demonstrator vehicle and its propulsion system. Future air-breathing space access vehicles offer advantages over conventional rocket-powered vehicles that must carry all of the oxidizer needed to burn their fuel. Air-breathing engine-powered vehicles obtain oxygen from the atmosphere in flight. The X-43C project will validate advanced technologies, design tools and test techniques that will enable design of such vehicles in the future.

For the three demonstration flights, a Pegasus-derived rocket booster will be air-launched by a carrier aircraft to boost the X-43C demonstrator vehicles to Mach 5 at approximately 80,000 feet. Flights will originate from Dryden/Edwards Air Force Base, Calif. Flight paths of the vehicles will be over water within the Pacific Test Range.

A ramjet, sometimes referred to as a stovepipe jet, or an athodyd, is a form of jet engine using the engine's forward motion to compress incoming air, without a rotary compressor. Ramjets cannot produce thrust at zero airspeed and thus cannot move an aircraft from a standstill.

A ramjet, sometimes referred to as a stovepipe jet, or an athodyd, is a form of jet engine using the engine's forward motion to compress incoming air, without a rotary compressor. Ramjets cannot produce thrust at zero airspeed and thus cannot move an aircraft from a standstill.

Ramjets require considerable forward speed to operate well, and as a class work most efficiently at speeds around Mach 3. This type of jet can operate up to speeds of Mach 6.

Ramjets can be particularly useful in applications requiring a small and simple engine for high speed use, such as missiles, while weapon designers are looking to use ramjet technology in artillery shells to give added range: it is anticipated that a 120-mm mortar shell, if assisted by a ramjet, could attain a range of 22 mi (35 km). Ramjets are frequently confused with pulsejets, which use an intermittent combustion, but ramjets employ a continuous combustion process, and are a quite distinct type of jet engine

Design

A ramjet is designed around its inlet. An object moving at high speed through air generates a high pressure region in front and a low pressure region to the rear. A ramjet uses this high pressure in front of the engine to force air through the tube, where it is heated by combusting some of it with fuel. It is then passed through a nozzle to accelerate it to supersonic speeds. This acceleration gives the ramjet forward thrust.

A ramjet is sometimes referred to as a 'flying stovepipe', a very simple device comprising an air intake, a combustor, and a nozzle. Normally the only moving parts are those within the turbopump, which pumps the fuel to the combustor in a liquid-fuel ramjet. Solid-fuel ramjets are even simpler.

By way of contrast, a turbojet uses a gas turbine driven fan to compress the air further. This gives greater efficiency and far more power at low speeds, where the ram effect is weak, but is also more complex, heavier and more expensive, and the temperature limits of the turbine section limits the top speed and thrust at high speed.

Inlet

Ramjets try to exploit the very high dynamic pressure within the air approaching the intake lip. Most ramjets operate at supersonic flight speeds and use one or more conical (or oblique) shock waves, terminated by a strong normal shock, to slow down the airflow to a subsonic velocity at the exit of the intake. The Inlet is divergent, to provide a constant inlet speed of Mach 0.5.

Combustor

As with other jet engines the combustor's job is to create hot air. It does this by burning a fuel with the air at essentially constant pressure. The airflow through the jet engine is usually quite high, so sheltered combustion zones are produced by using flame holders that stop the flames from blowing out.

Since there is no downstream turbine, a ramjet combustor can safely operate at stoichiometric fuel:air ratios, which implies a combustor exit stagnation temperature of the order of 2400 K for kerosene. Normally the combustor must be capable of operating over a wide range of throttle settings, for a range of flight speeds/altitudes. Usually a sheltered pilot region enables combustion to continue when the vehicle intake undergoes high yaw/pitch, during turns. Other flame stabilization techniques make use of flame holders, which vary in design from combustor cans to simple flat plates, to shelter the flame and improve fuel mixing. Overfuelling the combustor can cause the normal shock within a supersonic intake system to be pushed forward beyond the intake lip, resulting in a substantial drop in engine airflow and net thrust.

Nozzles

The propelling nozzle is a critical part of a ramjet design, since it accelerates exhaust flow to produce thrust.

For a ramjet operating at a subsonic flight Mach number, exhaust flow is accelerated through a converging nozzle. For a supersonic flight Mach number, acceleration is typically achieved via a convergent-divergent nozzle.

Performance and control

Below about Mach 0.5 they give little thrust and are highly inefficient due to their low pressure ratios.

Above this speed, given sufficient initial flight velocity, a ramjet will be self-sustaining. Indeed, unless the vehicle drag is extremely high, the engine/airframe combination will tend to accelerate to higher and higher flight speeds, substantially increasing the air intake temperature. As this could have a detrimental effect on the integrity of the engine and/or airframe, the fuel control system must reduce engine fuel flow to stabilize the flight Mach number and, thereby, air intake temperature to reasonable levels.

Due to the stoichiometric combustion temperature, efficiency is usually good at high speeds (Mach 2-3), whereas at low speeds the relatively poor compression ratio means that ramjets are outperformed by turbojets or even rockets.

Ramjet Types

Ramjets can be classified according to the type of fuel, liquid or solid; and the booster.

In a liquid fuel ramjet (LFRJ) hydrocarbon fuel (typically) is injected into the combustor ahead of a flameholder which stabilises the flame resulting from the combustion of the fuel with the compressed air from the intake(s). This offers a lower cost approach than a regulated LFRJ requiring a turbopump and associated hardware to supply the fuel.

A ramjet generates no static thrust and needs a booster to achieve a forward velocity high enough for efficient operation of the intake system. The first ramjet powered missiles used external boosters, usually solid-propellant rockets, either in tandem, where the booster is mounted immediately aft of the ramjet, e.g. SA-4 Ganef. A tandem booster increases the overall length of the system whereas wraparound boosters increase the overall diameter. Wraparound boosters will usually generate higher drag than a tandem arrangement.

Integrated boosters provide a more efficient packaging option since the booster propellant is cast inside the otherwise empty combustor. Integrated designs are complicated by the different nozzle requirements of the boost and ramjet phases of flight. Due to the higher thrust levels of the booster a different shaped nozzle is required for optimum thrust compared to that required for the lower thrust ramjet sustainer. This is usually achieved via a separate nozzle which is ejected after booster burnout. However, designs such as Meteor feature nozzleless boosters.

Integral rocket ramjet/ducted rocket

These are a slight variation on the ramjet where the supersonic exhaust from a rocket combustion process is used to compress and react with the incoming air in the main combustion chamber. This has the advantage of giving thrust even at zero speed.

In a solid fuel integrated rocket ramjet (SFIRR) the solid fuel is cast along the outer wall of the ramcombustor. In this case fuel injection is through ablation of the propellant by the hot compressed air from the intake(s). In a ducted rocket a solid fuel gas generator produces a hot fuel-rich gas which is burnt in the ramcombustor with the compressed air supplied by the intake(s). The flow of gas improves the mixing of the fuel and air and increases total pressure recovery. In a Throttleable Ducted Rocket (TDR), also known as a Variable Flow Ducted Rocket (VFDR), a valve allows the gas generator exhaust to be throttled allowing control of the thrust. Unlike an LFRJ solid propellant ramjets cannot flameout.

Flight speed

Even above the minimum speed a wide flight envelope (range of flight conditions), such as low to high speeds and low to high altitudes, can force significant design compromises, and they tend to work best optimised for one designed speed and altitude (point designs). However, ramjets generally outperform gas turbine based jet engine designs and work best at supersonic speeds (Mach 2-4). Although inefficient at slower speeds they are more fuel-efficient than rockets over their entire useful working range up to at least Mach 5.5.

The performance of conventional ramjets falls off above Mach 6 due to dissociation and pressure loss caused by shock as the incoming air is slowed to subsonic velocities for combustion. In addition, the combustion chamber's inlet temperature increases to very high values, approaching the dissociation limit at some limiting Mach number.

Related engines

Air turboramjet

Another example of this is the Air TurboRamjet (ATR) which has a compressor powered by a gas heated via a heat exchanger within the combustion chamber.

Scramjets

Ramjets always slow the incoming air to a subsonic velocity within the combustor. Scramjets, or "supersonic combustion ramjet" are similar to ramjets, but some of the air goes through the entire engine at supersonic speeds. This increases the stagnation pressure recovered from the freestream and improves net thrust. Thermal choking of the exhaust is avoided by having a relatively high supersonic air velocity at combustor entry.

In the scramjet, the ram air is not slowed to subsonic speeds for combustion and as a result, shocks are not encountered and pressure loss is avoided.

Precooled engines

A variant of the pure ramjet is the 'combined cycle' engine, intended to overcome the limitations of the pure ramjet. It uses liquid hydrogen fuel in a fairly exotic single-fan arrangement. The liquid hydrogen fuel is pumped through a heat exchanger in the air-intake, simultaneously heating the liquid hydrogen, and cooling the incoming air. This cooling of the incoming air is critical to achieving a reasonable efficiency. After mixing with the air it is burned in the combustion chamber.

The Reaction Engines Scimitar has been proposed for the LAPCAT hypersonic airliner, and the Reaction Engines SABRE for the Reaction Engines Skylon spaceplane.

Nuclear powered ramjets

During the Cold War the United States designed and ground-tested a nuclear-powered ramjet called Project Pluto. This system used no combustion - a nuclear reactor heated the air instead. The SR-71's Pratt & Whitney J58 engines act as turbojet-assisted ramjets at high-speeds (Mach 3.2).

Ionospheric ramjet

A concept was created by NASA for recombining this thin gas back to diatomic molecules at orbital speeds to power a ramjet.

Bussard ramjet

The Bussard ramjet is a space drive concept that is intended to fuse interstellar wind and exhaust it at high speed from the rear of the vehicle.